Transportation

AIMCO® engineers manufacture a wide variety of material handling solutions for the transportation industry. Our products help workers grip, clamp, pick, place, lift and control everything from engine blocks to transmission cases, vehicle frames to drive trains and more. Whatever your unique material handling needs, we have the experience and equipment to design and fabricate a lasting solution that delivers maximized return on investment.

Click on any of the videos below to see how our products can help you boost safety and productivity in your plant.

Engine Blocks

Mechanical gripping device handling cast aluminum engine blocks. The gripper was configured for an intelligent lifting device and used the hoist's cable anti-slack switch as part-present detection. The gripper was designed to handle millions of cycles per year.

Batteries

Automatic clamp and unclamping controller grabs and releases automotive and marine batteries. A force-sensing handle was used for the up and down controller, producing a button-free operation.

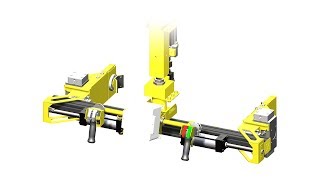

Transmission Cases

Force-sensing up down controller coupled with our autopick controller, giving the operator a button-less lift assist. Mechanical gripper with non-marring grip pads clamped transmission cases from the top for simple and straight forward material handling.

Tires & Wheels

Picking and placing large tires and wheels with a long stroke clamping gripper. Custom-engineered jaws contact four points on the outside of the wheel. Autopick controller made the factory worker's daily material handling much safer and much easier.

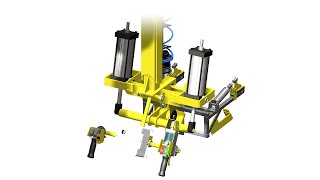

Drive Trains & Axles

Handling drive shafts with a dual gripper end effector, picking them out of packaging and into a press fixture. A two-hand button arangement was used to force the operator to use both hands when grabbing and releasing, further avoiding accidents, injuries, and waste.

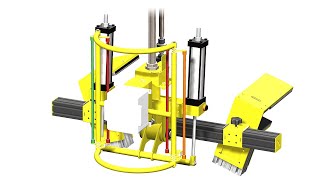

Engine Cradles

Turnkey lift assist with AIMCO torque tube, lifting cylinder, mechanical gripper, and a tilt 90 degrees assembly that easily grabs engine cradles from a flat orientation to an upright position. Ultimately picking from a pallet and placing into a shipping rack.

Exhaust Systems

Handling large tubes used for exhaust systems on John Deere tractors. A custom AIMCO dual gripper end effector with a power tilt 90 degrees function that maneuvered the tube into an orientation for palletizing. AIMCO's force-sensing pneumatic controller for up, down, grab, and release.

Brake Rotors

AIMCO's air-powered permanent magnets were used to pick and place brake rotors. Pound for pound, there is no stronger magnet on the planet. Hooked to an air hoist with a new and innovative AIMCO controller that ergonomically fits your left or right hand, using your index finger and middle finger for up and down control. A slide valve with dual task release was used to comfortably and ergonomically turn magnets on and off.

Hatchbacks

Vacuum end effector with two suction cups and one venturi vacuum generator handling rear hatchbacks. Lifting was accomplished with an AIMCO TorqLIFT and ergonomic friendly floating handlebars kept the operator in a comfortable zone.

Bumpers & Fenders

Large semi-truck bumpers up to 8ft wide can be handled with this AIMCO vacuum end effector. A patented safety set down interlock was used between the hoist and vacuum device to prevent the operator from dropping a load while suspended.

Doors

Composite doors were easily handled and manipulated with an AIMCO gripper with two different rotations; a power roll 90-degrees and a power tilt 90-degrees. Suspending and lifting the load and device with an AIMCO TorqLIFT kept the tooling and load stable and balanced, even though it was cantilvered a couple feet.

Radiators

Automotive radiators were picked out of a weld fixture with a custom mechanical gripper that harbored inline power tilt 90 degree mechanisms right on the jaws. The rotation circuit was designed to be incremental so the operator had infinite adjustment on the angle of the radiator.

Tailgates

Automatic and sequential pneumatic logic was used on this AIMCO solution to grab a tailgate, first by sealing a vacuum cup which signaled the actuating jaws to cycle, which in turn directed the grippers to clamp on the part. The solution delicately handled the rear door, gently, safely, and securely.

Torque Converters

Air powered mechanical gripper with a custom floating handlebar was configured for a standard electric chain hoist. The gripper jaws were specifically attach to the torque converters, grabbing them from a conveyor and placing them into boxes for shipping.

Small Part Containers

This below-the-hook lift device carefully handled plastic bins, each with several delicate piston valve stems. The gripper engaged the handles of the bin and automatically cycled between on and off via the Autopick controller.

Windshields

Vacuum lift assist designed for bus & coach windshields, can be used for all car windshields or sunroofs of similar shape and size. The vacuum system was air-powered with a pneumatic power tilt 90 degree feature built in.

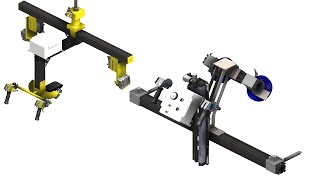

Vehicle Frames

Vehicle frame component transmission tunnel was carefully handled using an AIMCO vacuum lift assist with an articulated jib crane and TorqLIFT (lifting cylinder and torque tube). The lift assist even had an AIMCO pivoting handlebar to keep the operator ergonomic while placing the transmission tunnel into the shipping rack.